Don’t Just Comply, Perform

Changing the Way Inspections are Done

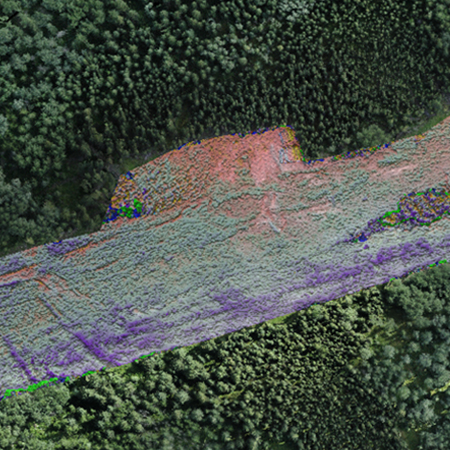

Photo by: Ryan Tulloch, ProDelta Projects Inc.

km of pipeline inspected anually

different analytics

Working in Regulatory compliance

ProDelta Projects Inc. Specializes in Remote Sensing and Data Analytics using photogrammetry technology introduces a new level of analytics that ensure clients stay within compliance and manage risk in a cost-effective manner.

ProDelta’s leading technology is changing the way inspections are done, ensuring the clients exceed their compliance requirements, with transparent data that can be easily searched.

ProDelta Projects Inc. has developed the Proactive Identify Planning Execution (PIPE) System that is focused on saving clients money and giving them both confidence and auditable regulatory compliance.

The PIPE Process can take thousands of km’s, identify high-risk locations and focus specialists on critical areas which can impact safe operations.

Data for Analytics is collected during regular flight patrols

If reassesment is required, data collected and analyzed through the PIPE Process can aid in the process provide a high level of cost certainty.

PROACTIVE

Utilize Open Source Data and Internal Systems To Optimize Programs

IDENTIFY

Use Remote Sensing and Data Analytics for Accurate Planning

PLAN

Design, Create Cost Estimates and Provide Scheduling Support

EXECUTE

Data Automation, Machine Control Support, Remediation/Reclamation

Proactive

BEFORE LEAVING THE OFFICE

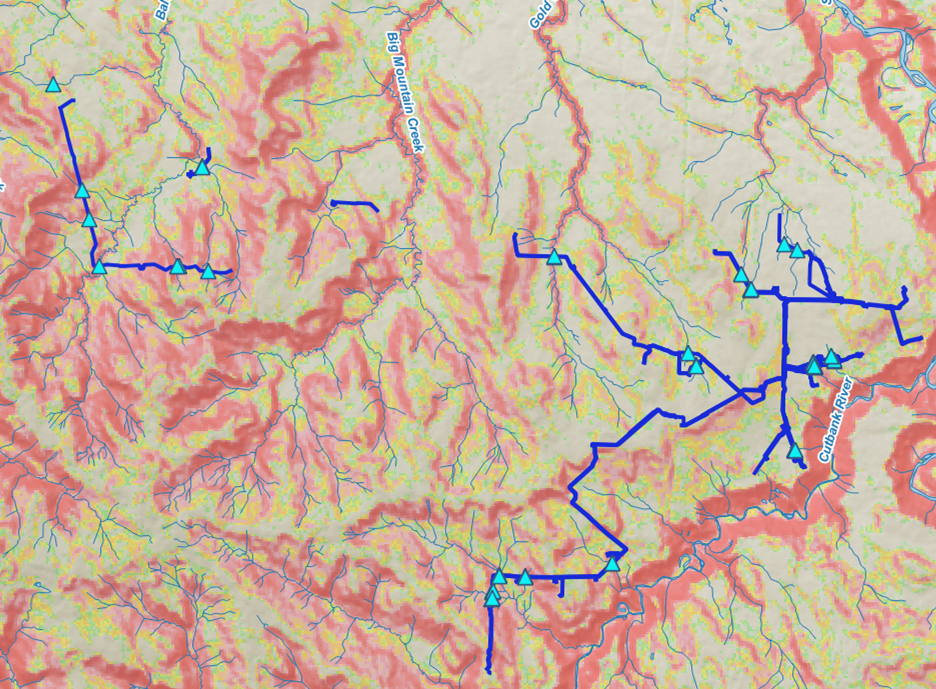

ProDelta has developed its internal geospatial system to utilize both client and open-source data to analyze linear infrastructure. During the process, ProDelta working with the client takes existing data and utilizes analytics to extrapolate potential high-risk areas. This includes but not limited to:

• Age of Infrastructure

• Potential Geohazards,

• High Risk Creek Crossings

• Infrastructure Substance

These analytics are implemented into a monitoring program that can be implemented later during inspection.

ProDelta has developed a series of different interactive dashboards to that are free to use as part of our process, allowing stakeholders to view their information in convenient methods not seen before.

BUSINESS INTELLIGENCE DASHBOARD

Take a look for free at one of our available Business Intelligence Dashboards on Alberta Creek Crossings.

identify

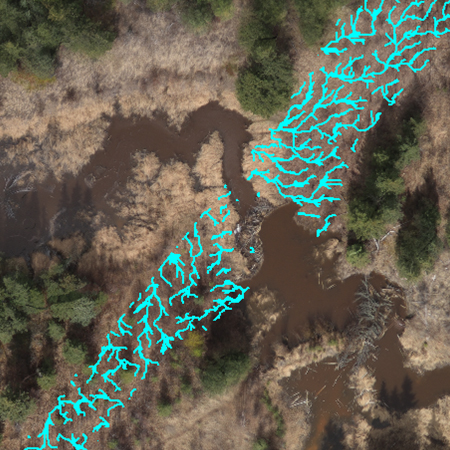

Photogrammetry utilizes high resolution photos to measure. This is similar to LIDAR technology. It is cost effective, can be integrated into routine aerial patrol, and derives valuable analytics.

During schedueld aerial inspections, the ProDelta Photogrammetry sensor captures a high resolution every 2 seconds and is programmed to follow the pipeline ROW. High-Risk areas identified during the data review or during the inspection have additional data captured in minutes. Following the collection of data, ProDelta can generate two different outputs:

• High-Resolution NADAR Photos for low-risk areas:

• Processed Data for High-risk areas, which entails:

• High-Resolution Orthomosaic

• Colourized Point Cloud/3D Mesh

• Digital Surface Model

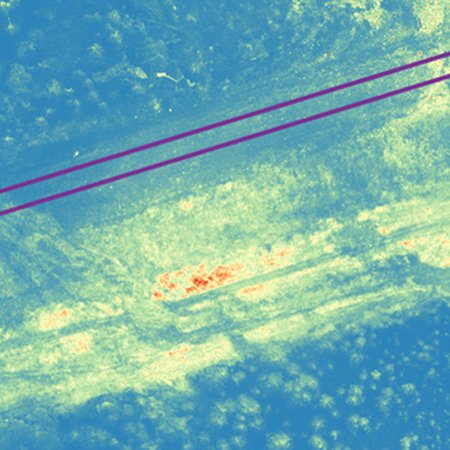

Comparison of Satellite Imagery vs Data Collection During Pipeline Inspection, Identifying a high risk beaver dam.

Analytics

The processed data collected through photogrammetry collected during ProDelta’s aerial inspections is able to derive a series of analytics valuable to our clients in the long term, such as:

VEGETATION HEALTH

The human eye is limited to seeing only green light waves. However unhealthy vegetation gives off an abundance of Near Infra-Red light. Using Remote Sensing, clients have the ability to see the vegetation health of their footprint compared to offsite. Benefits of the vegetation health analytics are:

• Transparent Data for All Stake Holder • Statistical Comparison

• Repeatable for longer term monitoring

SURFACE DRANAGE ANALYSIS

Utilizing ProDelta’s surface drainage analysis, construction professionals can see how surface water can impact the pipeline ROW. Surface Drainage Analysis helps construction planning with:

• Diversion Berm Placement

• Erosion Controls

• Slope Stability Issues.

Change detection

In areas that are high potential of slope stability, ProDelta can compare different monitoring events to determine potential movement.

Plan

Reporting

ProDelta believes that the start of a good plan, starts with easy to understand data.

Using ProDelta DMS portals, our users have the ability to view their data inside our interactive GIS platform, or have a quick summary through our business intelligence portal.

Focused Ground Truthing and Measurement

ProDelta has in-house survey staff to complete detailed surveys for revetment execution. ProDelta’s team can collect data which includes but is not limited to:

- Depth of Cover

- Potential Movement

- Steam Capacity Assessment

Detailed site drawings are developed to work with Engineers and Environmental Specialists to optimize the revetment process.

Execution PLANNING AND schedule

Working with in-house estimators and schedulers, ProDelta can generate a cost estimate and associated schedule which provides a high level of cost certainty for approved revetment.

Execute

During execution with approved contractors, ProDelta’s field technical staff can support machine control, quantity survey and automate data required for all integrity digs.

machine control

Machine Control is a paradigm shift in the way equipment operation is completed at the frontline. ProDelta is utilizing GPS technology in order to give equipment operators extreme confidence and high levels of accuracy while operating, as well as generating a better understanding of the process.

9303 109 Street

Fort St John, BC

V1J 6K6

HOME

ABOUT

TOOLS

MOBILE APP

CONNECT WITH US

© COPYRIGHT PRODELTA PROJECTS INC 2021. ALL RIGHTS RESERVED.

WEBSITE DESIGNED BY MECCA BRANDING LAB INC

9303 109 Street

Fort St John, BC

V1J 6K6

HOME

ABOUT

TOOLS

MOBILE APP

CONNECT WITH US

© COPYRIGHT PRODELTA PROJECTS INC 2021. ALL RIGHTS RESERVED.

WEBSITE DESIGNED BY MECCA BRANDING LAB INC